Description

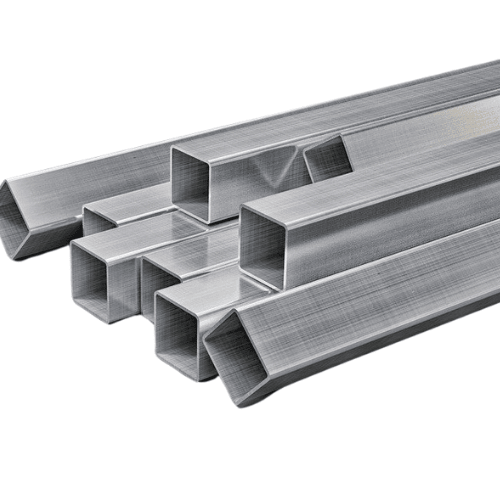

Square tubing, also known as square hollow structural sections (HSS), is a versatile and robust construction material widely utilized across various industries. Its unique geometric profile offers uniform strength characteristics, making it an ideal choice for applications requiring stability and load-bearing capacity.

Material Composition and Manufacturing Process

Square tubes are predominantly fabricated from structural steel, adhering to standards such as ASTM A500 or ASTM A1085. The manufacturing process involves forming flat steel plates into a round shape, welding the edges to create a mother tube, and then reshaping it into a square profile through a series of forming stands.

This method ensures uniform wall thickness and consistent structural integrity throughout the tube.

Key Characteristics

Structural Integrity: The uniform geometry of square tubing provides exceptional strength and stability, making it suitable for applications subjected to multi-directional loading.

Corrosion Resistance: When manufactured from materials like stainless steel or treated with protective coatings, square tubes exhibit high resistance to corrosion and moisture, enhancing their durability in various environments.

Versatility: The flat surfaces of square tubing facilitate easy welding, drilling, and cutting, allowing for seamless integration into diverse structural frameworks.

Aesthetic Appeal: The clean lines and smooth surfaces of square tubes contribute to modern architectural designs, offering both functional support and visual appeal.

Common Applications

Square tubing’s adaptability makes it a preferred choice in numerous sectors:

Construction: Utilized in building frameworks, columns, and support beams due to its load-bearing capabilities and ease of installation.

Automotive: Employed in manufacturing vehicle frames and chassis components, providing strength without significantly increasing weight.

Furniture: Used in crafting durable and stylish furniture pieces, such as tables and chairs, owing to its structural integrity and aesthetic versatility.

Safety Railings: Ideal for constructing railings and barriers, ensuring safety in residential and commercial settings.

Advantages Over Other Structural Materials

Compared to other structural materials, square tubing offers distinct benefits:

Enhanced Load Distribution: Its uniform shape ensures an even distribution of stress, reducing the risk of structural failure.

Torsional Resistance: Exhibits superior resistance to twisting forces, making it suitable for applications where torsion is a concern.

Efficient Fabrication: The consistent dimensions and smooth surfaces allow for precise fabrication, reducing labor and material costs.

Considerations for Selection

When choosing square tubing for specific applications, consider the following factors:

Material Grade: Select the appropriate steel grade (e.g., ASTM A500 Grade B or C) based on the required mechanical properties.

Wall Thickness: Determine the necessary wall thickness to withstand anticipated loads and stresses.

Surface Treatment: Consider galvanization or painting for applications exposed to corrosive environments to extend the tubing’s lifespan.